More than 80% of Campbell Grinder machines are built to order so they meet the customer’s unique requirements.

Hundreds of hours of engineering ensure each machine will produce parts of the highest possible quality. The Campbell Grinder standard modules described below are all available in customizable configurations.

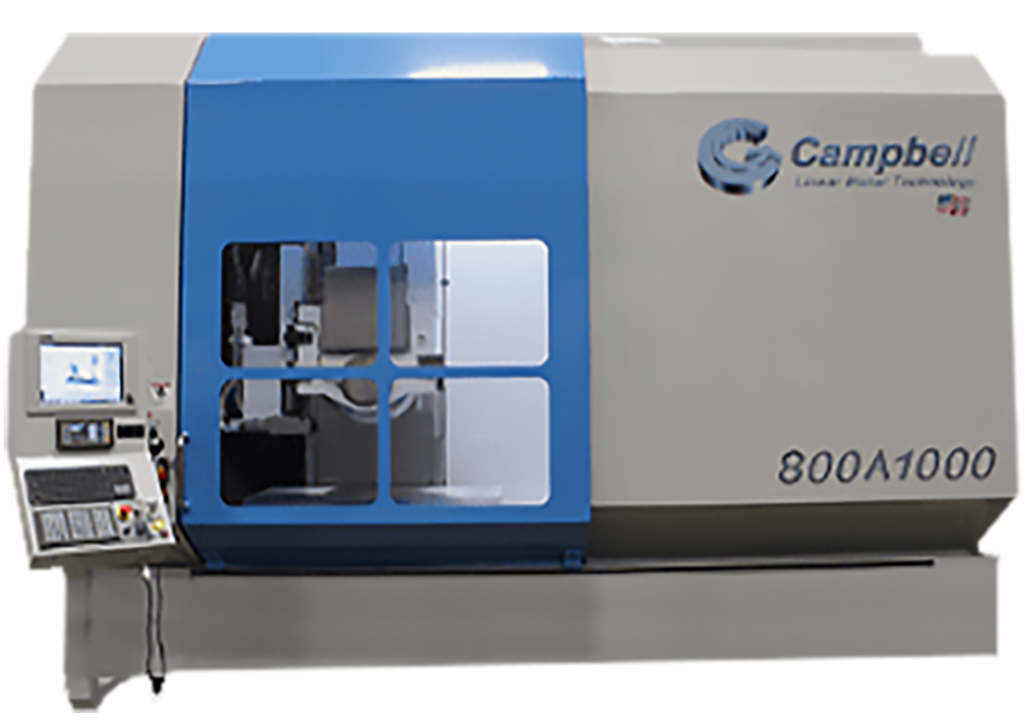

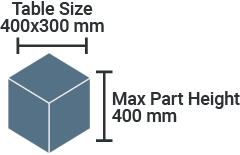

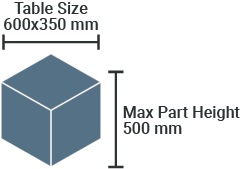

Creep Feed Grinders

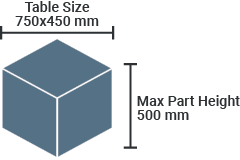

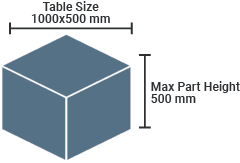

Campbell Grinder creep feed grinders are optimized for processes that require 3 or 4 linear axes and include unique dimensions, applications, programming, and features. All three structural guideway rail-mating components have a large closed box cross-section, maximizing grinding stiffness and geometric accuracy. These traveling column creep feed grinders feature a Y-axis ram traveling on the Z-axis and a stationary workpiece, allowing for a very small machine footprint.

Max Part Height

Spindle HP

Axes

0-3600 RPM

20-60 HP

X, 5 Microns (0.0002”)

Y, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

400x300mm

60HP

X, Y, Z

0-5000 RPM

20-60 HP

X, 5 Microns (0.0002”)

Y, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

600x400mm

60HP

X, Y, Z

0-5000 RPM

20-60 HP

X, 5 Microns (0.0002”)

Y, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

800x600mm

60HP

X, Y, Z

0-5000 RPM

60-100 HP

X, 5 Microns (0.0002”)

Y, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

1000x600mm

60HP

X, Y, Z

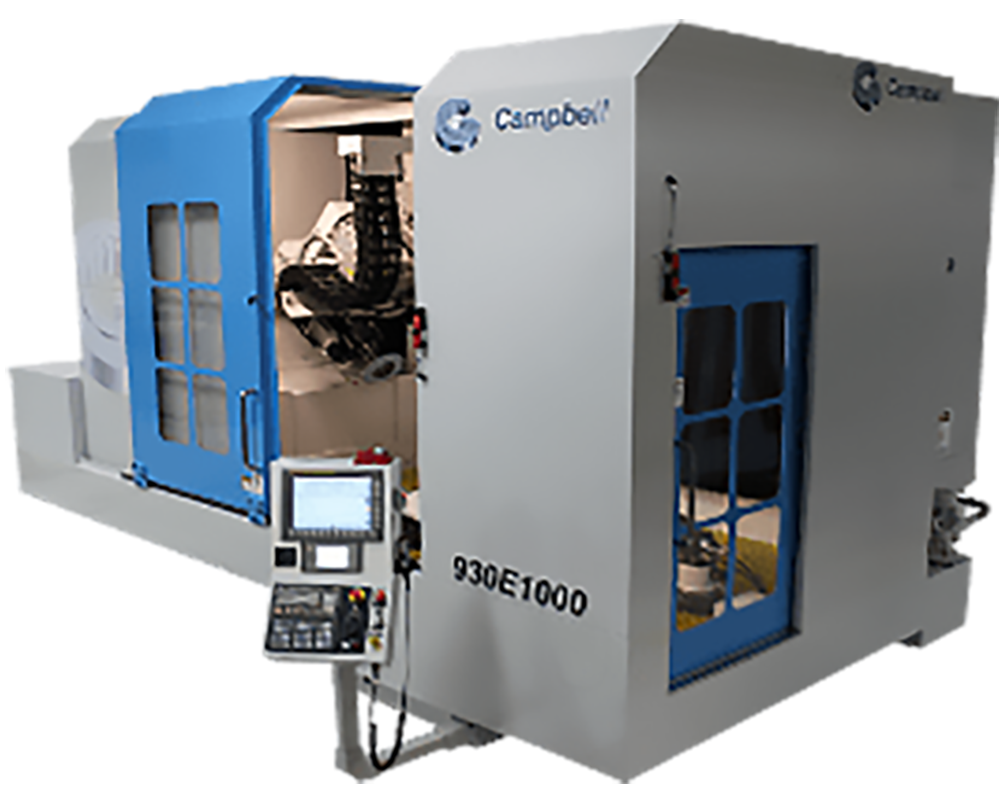

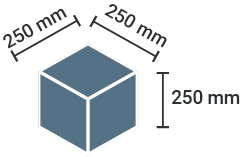

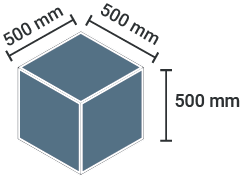

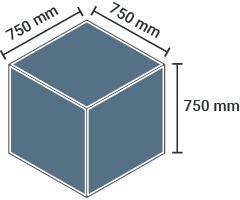

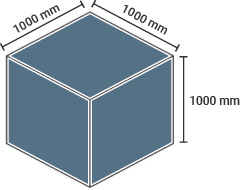

5 Axis Grinders

Campbell Grinder 4 and 5 axes vertical grinders are engineered to grind with any abrasive or superabrasive including plated or vitrified CBN, or any aluminum oxide and ceramic blend grinding wheel. These vertical grinders are especially well suited for grinding turbine engine vanes, turbine engine buckets, turbine engine shrouds, turbine engine hangers, turbine engine panels, and fairings ranging in size from small jet engine vanes to large land based turbine parts. Optional features include automatic wheels and coolant nozzle changers and capabilities such as milling, drilling, and probing.

Spindle HP

Axes

0-7200 RPM*

30-60 HP

X, 5 Microns (0.0002”)

Y, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

B, 5 Arc Seconds

C, 5 Arc Seconds

250mm

60HP

X, Y, Z, B, C

0-7200 RPM*

30-60 HP

X, 5 Microns (0.0002”)

Y, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

B, 5 Arc Seconds

C, 5 Arc Seconds

500mm

60HP

X, Y, Z, B, C

0-7200 RPM*

30-60 HP

X, 5 Microns (0.0002”)

Y, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

B, 5 Arc Seconds

C, 5 Arc Seconds

750mm

60HP

X, Y, Z, B, C

0-7200 RPM*

30-100 HP

X, 5 Microns (0.0002”)

Y, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

B, 5 Arc Seconds

C, 5 Arc Seconds

1000mm

100HP

X, Y, Z, B, C

* Other Speeds Available

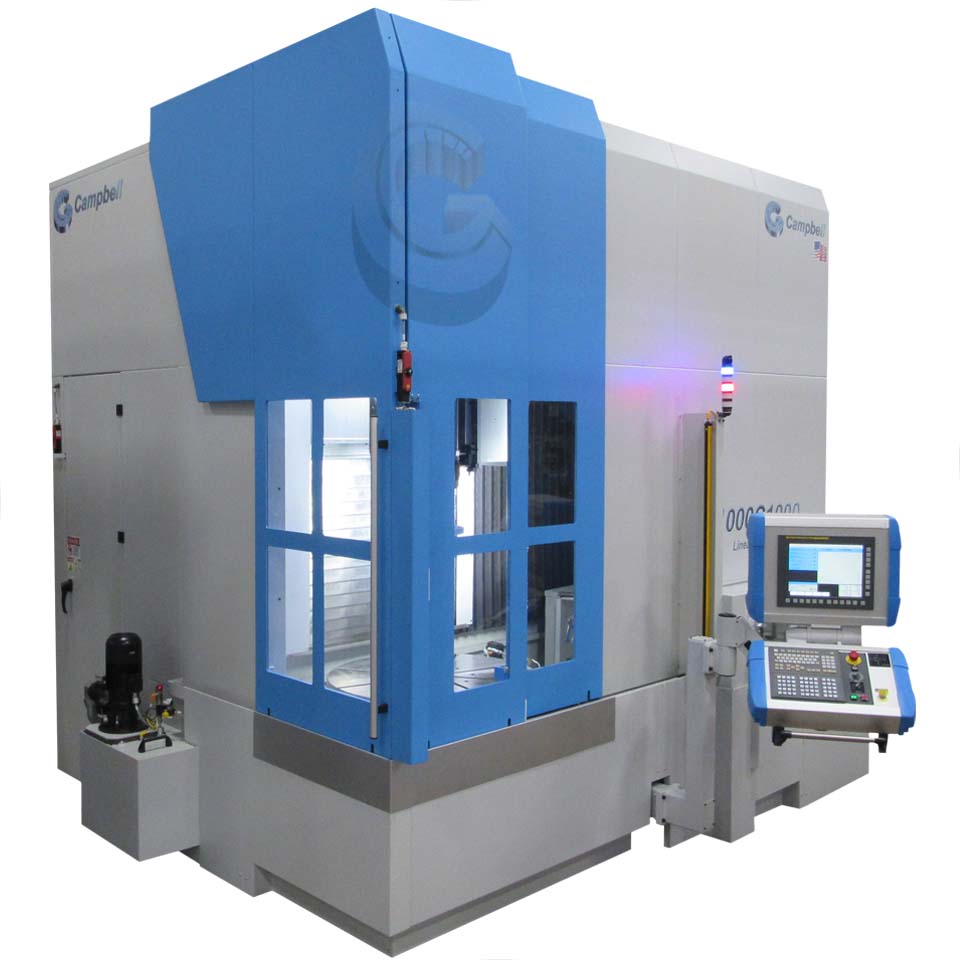

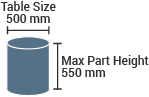

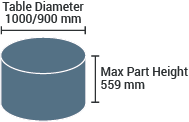

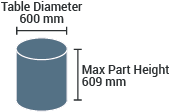

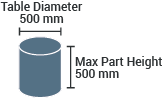

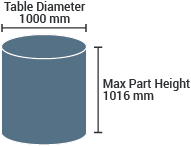

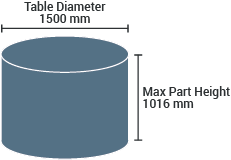

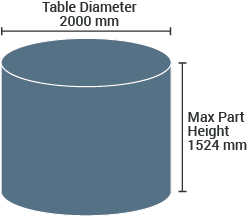

Vertical Grinders

Campbell Grinder vertical grinders have the ability to grind ID, OD, faces, tapers, and curvic while in a vertical configuration and are designed specifically to perform precision grinds on cylindrical parts. Bearings, curvic couplings, honeycomb rings, stator cases, gears, sprockets, shafts, vane rings, and more can be finely ground on these cylindrical grinders.

Max Part Height

Spindle RPM

Spindle RPM

Axes

1067 mm

25 HP

1500-7200 RPM

X, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

B, 10 Arc Seconds

C, 5 Microns (0.0002”)

1000mm

1500-7200RPM

X, Z, B, C

800 mm

20 HP

1500-8500 RPM

X, 2.5 Microns (0.0001”)

Z, 2.5 Microns (0.0001”)

B, 5 Arc Seconds

C, 0.0004”

600mm

1500-8500RPM

X, Z, B, C

660 mm

15 HP

1500-7500 RPM

X, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

B, 2.5 Microns (0.0001”)

C, 2.5 Microns (0.0001”)

500mm

1500-7500RPM

X, Z, B, C

1143 mm

25-40 HP

1500-7500 RPM

X, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

B, 2.5 Microns (0.0001”)

C, 2.5 Microns (0.0001”)

1000mm

1500-7500RPM

X, Z, B, C

1651 mm

25-60 HP

1500-7200 RPM

X, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

B, 2.5 Microns (0.0001”)

C, 2.5 Microns (0.0001”)

1500mm

1500-7200RPM

X, Z, B, C

2159 mm

25-60 HP

1500-7200 RPM

X, 5 Microns (0.0002”)

Z, 5 Microns (0.0002”)

B, 2.5 Microns (0.0001”)

C, 2.5 Microns (0.0001”)

2000mm

1500-7200RPM

X, Z, B, C

Custom Grinders

Campbell Grinder engineers and application designers develop unique machines, including those shown below, to meet our customers’ most demanding applications. Contact us to find out how we can develop a unique solution for your specific part processing requirements.

Max Part Height

Spindle RPM

Axes

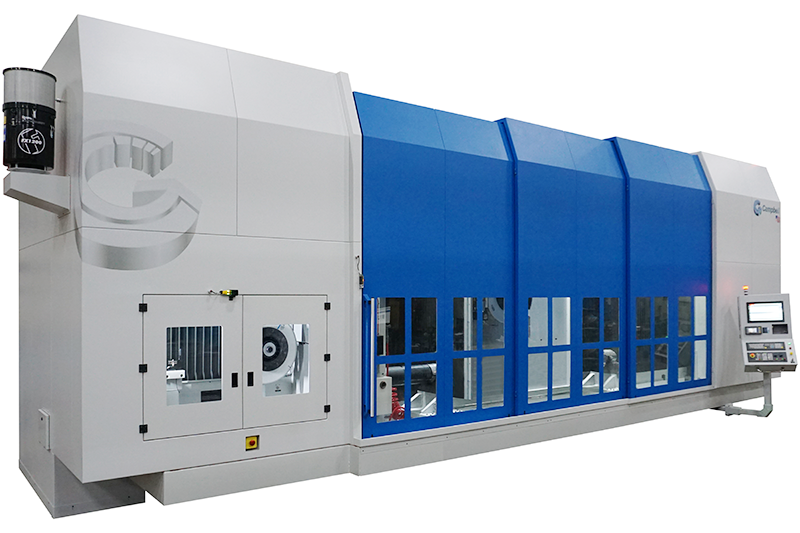

Microtech Coolant Filtration Systems

Campbell Grinder filtration systems are used throughout the metalworking industry worldwide for handling both water-based coolants and oil on the most demanding and challenging filter applications. We apply our 50+ years of precision grinding and filtration experience to design and manufacture our MicroTech line of filtration machinery and customizable add-ons.

Coolant Type

15-20 microns

Inclined Bed

Roll Media

Vacuum Filter

Oil or Water-Based

40-60 inches

425-1600 gal

15-20 microns

Oil or Water-Based

5-20 microns

Permanent Media

Drum Cellulose

Vacuum Filter

Oil or Water-Based

NA

NA

5-20 microns

Oil or Water-Based