PROBLEMS SOLVED.

Campbell Grinder Company solves manufacturers’ most challenging grinding problems by designing and manufacturing the best vertical, creep feed, and 5-axis grinding machines available. This allows our OEM and Tier 1 customers to produce the highest quality parts, at the lowest overall cost-per-part.

Looking for consistency and reliability in your production grinding? Campbell Grinder Company is an American leader in providing fully customizable grinding machines. Each grinder that leaves our factory is the result of hundreds of hours of engineering to determine the best possible method to produce our customers' parts.

Our Machines

While Campbell Grinder machines are available in a standard configuration, more than 80% are customized for the end use. We design and manufacture:

Our Processes

Each step of the Campbell Grinder process is designed to yield the best possible machine and results.

Our Value to You

Solving our customers’ grinding problems by engineering and building machines that far exceed their expectations of precision, consistency, reliability, and longevity.

Sales

Study our customer's specific challenges, meet with our Engineers, then present potential solutions.

Mechanical & Electrical Engineering

Communication from our Sales to Engineering Teams, then onto our engineering evaluation processes, which are built on over 50-years of expertise.

Front-end Application Development

Our in-house Applications Team begins customizing the machine's back-end programming and front-end interface.

Machine Building

Skilled and experienced grinding Machine Builders are mobilized to build something that combines ultra-precision with robust longevity.

In-house Testing

Full testing, including metrology, laser positioning, circular interpolation, geometric alignment, and vibration tests

On-site Installation

Machine Builders and Installers collaborate at the customer's site, then reassemble and re-test to ensure that all customer expectations are met and exceeded.

Service and Maintenance

Experienced Field Service Techs respond quickly and skillfully to PM, service, or warranty needs.

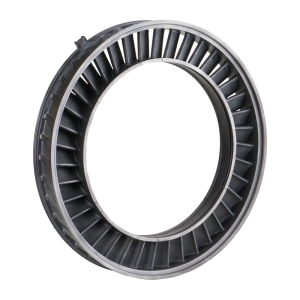

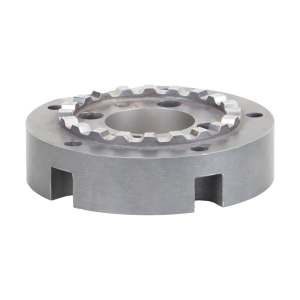

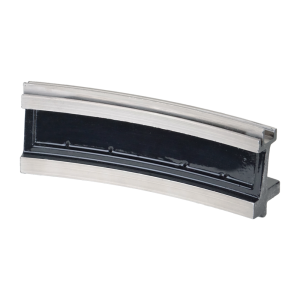

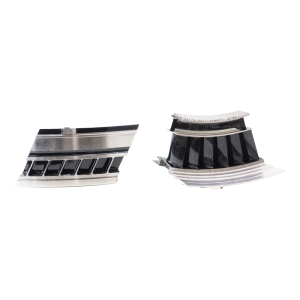

Applications

Campbell Grinder customers include manufacturers of aerospace engines and land-based military applications as well as high-production and job shops. Depending on the model, our machines can creep feed grind, ID grind and OD grind, taper grind, and form grind using conventional or super abrasive technology. They can also grind radial slots, arcs, faces, and many other surfaces. Multi-functional machinery is our specialty, so our machines not only grind but in many cases also turn, mill, drill, and probe if required.